- Home

- Products

- Flexographic Presses

- Servo Driven Inline Flexo Printing Press, FY Series

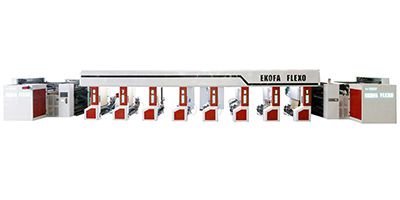

Flexo Printing Press, FY Series

Servo Driven In-Line Flexographic Printing Machine for Paper and Cardboard Printing

- Printing repeat: 380mm-800mm

- Max. unwind diameter: 60'' (1524mm)

- Max. rewind diameter: 60" (1524mm)

- Max. mechanical speed: 260m/min (853fpm)

- Substrate: 25-400gsm

Our FY series in-line flexographic printing machine is a fully servo controlled electronic line shaft gearless flexo printing press suited for a variety of applications including paper cup blank printing, paper bag printing, food & beverage packaging printing, pharmaceutical box printing, etc. The printing press combines servo driven sleeve system and stable tension control system, and offers a printing width range of 660-1450mm. A single machine of this series flexo printing press is capable enough to handle high-quality printing on substrates ranging from lightweight paper to heavyweight cardstock.

Printing Examples

Applications

- Food & Beverage Packaging Printing

- Paper Cup Blank Printing

- Paper Bag Printing

- Pharmaceutical Box Printing

Features

- Full-servo control, shaftless transmission and gearless design, satisfying various customers’ needs;

- Machine body is constructed by casting process, ensuring robust structure and smooth operation;

- Servo drive allows user to print on various substrates, meeting more printing applications needs;

- Gearless servo drive transmission delivers wider flexo printing applications without printing pitch restrictions of 1/8" (3.175mm), efficiently avoiding banding defect;

- Servo control guarantees precise register in both longitudinal and transverse directions;

- Closed-loop tension control system provides high tension stability in roll unwinding or rewinding;

- Fully automatic web guiding helps automatic guiding of a continuous web;

- Configured with pre-register and auto-register control, production speed and qualification rate can be significantly increased;

- Easy-to-use control console allows to achieve automatic operation, and the operation data is clearly shown via user interface;

- Fault diagnosis system assists users in quick troubleshooting;

- Automatic butt splicer is optional for non-stop unwinding and rewinding;

- Remote communication function is configurable to realize remote fault diagnosis;

- More optional configurations for your individual demands, such as automatic cleaning unit, etc.;

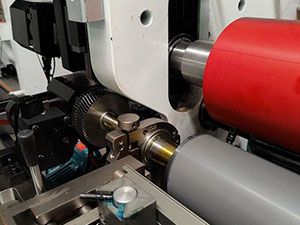

Details

Model Options

-

-

Max. web width

-

34.25'' (870mm)

-

-

Max. printing width

-

32.67'' (830mm)

-

-

Max. web width

-

37.00'' (940mm)

-

-

Max. printing width

-

35.43'' (900mm)

-

-

Max. web width

-

40.16'' (1020mm)

-

-

Max. printing width

-

38.58'' (980mm)

-

-

Max. web width

-

44.09'' (1120mm)

-

-

Max. printing width

-

42.52'' (1080mm)

-

-

Max. web width

-

51.57'' (1310mm)

-

-

Max. printing width

-

49.21'' (1250mm)

-

-

Max. web width

-

57.87'' (1470mm)

-

-

Max. printing width

-

55.51'' (1410mm)

EKOFA FLEXO is over 20 years of experience in the flexo printing industry. As an experienced flexographic printing machine manufacturer, we can design and produce advanced flexographic press systems that solve your need for the economic and reliable performance in the flexible packaging printing and converting industry. We are capable of offering packaging manufacturers and users from the printing industry with a variety of configurations to perfectly suit their specific tasks. Our printing systems are highly efficient and able to handle the entire press printing process including pre-printing, coating, drying, die cutting, slitting, etc. Our flexographic print solutions can bring added value to various applications in package converting. If you would like more information about our flexo presses and services, please feel free to email us or give us a call.