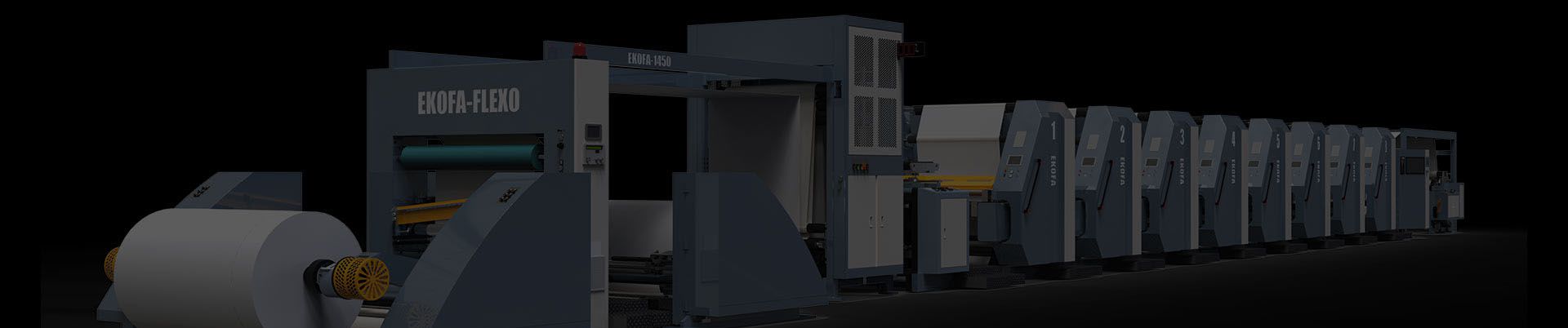

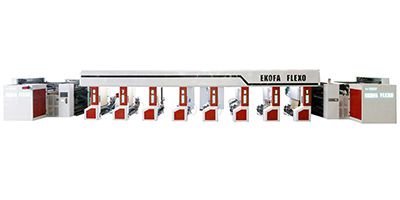

Flexo Printing Machines

At EKOFA FLEXO we are dedicated to design and manufacture flexographic printing presses. Our printing presses have been granted over 40 national patents. With over 20 years of experience in the printing industry, we have positioned ourselves in the vanguard of research, production, company scale, manufacturing facilitates, and after-sales service in the competitive domestic market.

-

Unwinding & Rewinding

Unwinding & RewindingThe unwinding and rewinding units can be offered in different configurations to accommodate to customer’s individual production demands, they can be combined with automatic butt splicer to ensure nonstop feeding of web materials. Our shaftless unwind and rewind stands are available in options of 3-inch, 6-inch and 12-inch chucks and cores for customer specific needs. Electric motor control or hydraulic cylinder is optional for web loading and rewinding.

-

Printing

PrintingWe provide unique printing solution by offering appropriate printing units tailored to customer’s requirements of product type, material, web width and printing speed. Please visit our product pages for specifications and features.

-

Control System

Control SystemWith regards to different printing needs of different customer, we offer choices of cost-effective or high-end configurations. In particular, our control systems are available in drive shaft transmission, electronic line shaft single-servo transmission, dual-servo transmission and full servo transmission control. Printing speed is optional, e.g. 150m/min, 200m/min, 260m/min, 300m/min.

-

Drying

The drying unit can be independently customized by utilizing electric heating, steam heating or natural gas heating methods per customer preferences.

-

Configurable and Expandable Units

We can provide a range of additional in-line processing equipment, such as corona treatment unit, electrostatic dedusting system, laminating unit, foil stamping unit, coating unit, slitting unit, die cutting unit, etc., and optional configurations of automatic register, second pass printing, automatic loading and unloading, automatic cleaning, automatic web threading, plate changing by manipulator arm, and more functions to meet customer applications needs.