- Home

- Products

- Flexographic Presses

- Inline Flexo Printing Press, HC Series

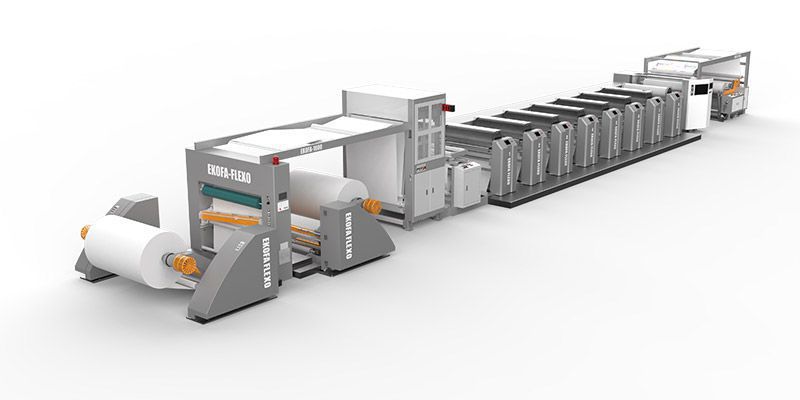

Flexo Printing Press, HC Series

In-Line Flexographic Printing Machine for Paper and Cardboard Printing

- Max. unwind diameter: 60'' (1524mm)/ 40" (1016mm)

- Max. rewind diameter: 60'' (1524mm)/ 40" (1016mm)

- Max. mechanical speed: 200m/min (650fpm)

- Substrate: 30-100gsm/ 80-250gsm/ 100-350gsm

This series in-line flexographic printing press is primarily designed for printing paper and cardboard substrates, applicable to print on paper cups, paper bags, pharma boxes, paper food containers and other paper packaging products. The printing width of flexo press ranges from 830mm to 1600mm, and the repeat length ranges between 279.4mm and 1200.15mm. This flexo printing press is a reliable and cost-effective printing solution to represent the best value for customer’s business, emphatically in fields of paper cup and paper bowl printing, it is particularly appreciated by our customers worldwide.

Printing Examples

Applications

- Paper Cup Printing

- Paper Bag Printing

- Paper Food Container Printing

- Pharma Box Printing

- More Paper Packaging Product Printing

Features

- Machine body is constructed by casting process, providing increased durability;

- Full-servo control, ensuring smooth running and fast reacting;

- Printing unit adopts one-piece plate cylinder body coupled with side bearers, achieving fast job changeovers;

- Exceptional supporting structure enables printing pressure to be precisely adjusted;

- Automatic pre-register setting allows for faster machine make-ready with less paper waste, efficiently lowering the cost to a minimum;

- Remote fault diagnosis system assists users in quick troubleshooting;

- Automatic butt splicer is used for non-stop unwinding and rewinding without slowing or stopping the process, greatly increasing production efficiency and reducing material waste;

- Air circulation system features adjustable air volume, providing high energy efficiency;

- More configurations for your individual demands, such as chambered doctor blade, automatic cleaning unit, etc.;

Details

Model Options

-

-

Max. web width

-

34.25'' (870mm)

-

-

Max. printing width

-

32.67'' (830mm)

-

-

Printing repeat

-

282.6mm-901.7mm/301.6mm-1200.1mm

-

-

Max. unwind diameter

-

60'' (1524mm)

-

-

Max. rewind diameter

-

60'' (1524mm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

37.00'' (940mm)

-

-

Max. printing width

-

35.43'' (900mm)

-

-

Printing repeat

-

282.6mm-901.7mm/301.6mm-1200.1mm

-

-

Max. unwind diameter

-

60'' (1524mm)

-

-

Max. rewind diameter

-

60'' (1524mm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

40.16'' (1020mm)

-

-

Max. printing width

-

38.58'' (980mm

-

-

Printing repeat

-

282.6mm-901.7mm/ 301.6mm-1200.1mm /301.6-1597.02mm

-

-

Max. unwind diameter

-

60'' (1524mm)

-

-

Max. rewind diameter

-

60'' (1524mm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

44.09'' (1120mm)

-

-

Max. printing width

-

42.52'' (1080mm)

-

-

Printing repeat

-

282.6mm-901.7mm/301.6mm-1200.1mm/301.6-1597.02mm

-

-

Max. unwind diameter

-

60'' (1524mm)

-

-

Max. rewind diameter

-

60'' (1524mm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

51.57'' (1310mm)

-

-

Max. printing width

-

49.21'' (1250mm)

-

-

Printing repeat

-

282.6mm-901.7mm/301.6mm-1200.1mm/301.6-1597.02mm

-

-

Max. unwind diameter

-

60'' (1524mm)

-

-

Max. rewind diameter

-

60'' (1524mm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

57.87'' (1470mm)

-

-

Max. printing width

-

55.51' (1410mm)

-

-

Printing repeat

-

282.6mm-901.7mm/301.6mm-1200.1mm/301.6-1597.02mm

-

-

Max. unwind diameter

-

60'' (1524mm)

-

-

Max. rewind diameter

-

60'' (1524mm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

Sleeve Type Narrow-web Flexo Printing

-

-

Max. web width

-

10.79" (274mm)

-

-

Max. printing width

-

10" (254mm)

-

-

Printing repeat

-

280-600mm

-

-

Max. unwind diameter

-

40" (1016mm)

-

-

Max. rewind diameter

-

40" (1016mm)

-

-

Max. mechanical speed

-

200m/min (650fpm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

13.78" (350mm)

-

-

Max. printing width

-

13" (330mm)

-

-

Printing repeat

-

280-600mm

-

-

Max. unwind diameter

-

40" (1016mm)

-

-

Max. rewind diameter

-

40" (1016mm)

-

-

Max. mechanical speed

-

200m/min (650fpm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

17.32" (440mm)

-

-

Max. printing width

-

16.5" (420mm)

-

-

Printing repeat

-

280-600mm

-

-

Max. unwind diameter

-

40" (1016mm)

-

-

Max. rewind diameter

-

60" (1524mm)

-

-

Max. mechanical speed

-

200m/min (650fpm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

21.26" (540mm)

-

-

Max. printing width

-

20.5" (520mm)

-

-

Printing repeat

-

280-600mm

-

-

Max. unwind diameter

-

60" (1524mm)

-

-

Max. rewind diameter

-

60" (1524mm)

-

-

Max. mechanical speed

-

200m/min (650fpm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

-

-

Max. web width

-

26.38" (670mm)

-

-

Max. printing width

-

25.5" (650mm)

-

-

Printing repeat

-

280-600mm

-

-

Max. unwind diameter

-

60" (1524mm)

-

-

Max. rewind diameter

-

60" (1524mm)

-

-

Max. mechanical speed

-

200m/min (650fpm)

-

-

Substrate

-

30-100gsm/80-250gsm/100-350gsm

EKOFA FLEXO is over 20 years of experience in the flexo printing industry. As an experienced flexographic printing machine manufacturer, we can design and produce advanced flexographic press systems that solve your need for the economic and reliable performance in the flexible packaging printing and converting industry. We are capable of offering packaging manufacturers and users from the printing industry with a variety of configurations to perfectly suit their specific tasks. Our printing systems are highly efficient and able to handle the entire press printing process including pre-printing, coating, drying, die cutting, slitting, etc. Our flexographic print solutions can bring added value to various applications in package converting. If you would like more information about our flexo presses and services, please feel free to email us or give us a call.